Environment

PWT Group is aware that we have a substantial environmental footprint, and we are committed to reduce this. We want to reduce our negative impact on the environment and climate by continuously improving internal processes and supporting suppliers on their journey towards more environmental-friendly production methods.

Climate

PWT is measuring its carbon footprint through an online reporting system provided by CEMAsys. The reporting system follows the GHG Protocol and ISO14064, and the aim is to map our emissions and track the progress on reducing GHG emissions throughout the business.

See our latest report below.

Responsibly Made

The most sustainable garments are quality products that will last for many years. In recent years PWT Group has worked to reduce the number of styles and gain a better quality and durability for each garment. Our premium brands, Bison and Lindbergh Black are a big part of this. Until now, we have achieved a 57% reduction in styles (compared to 2017 data). This development is very much in line with coming EU legislation within the textile industry.

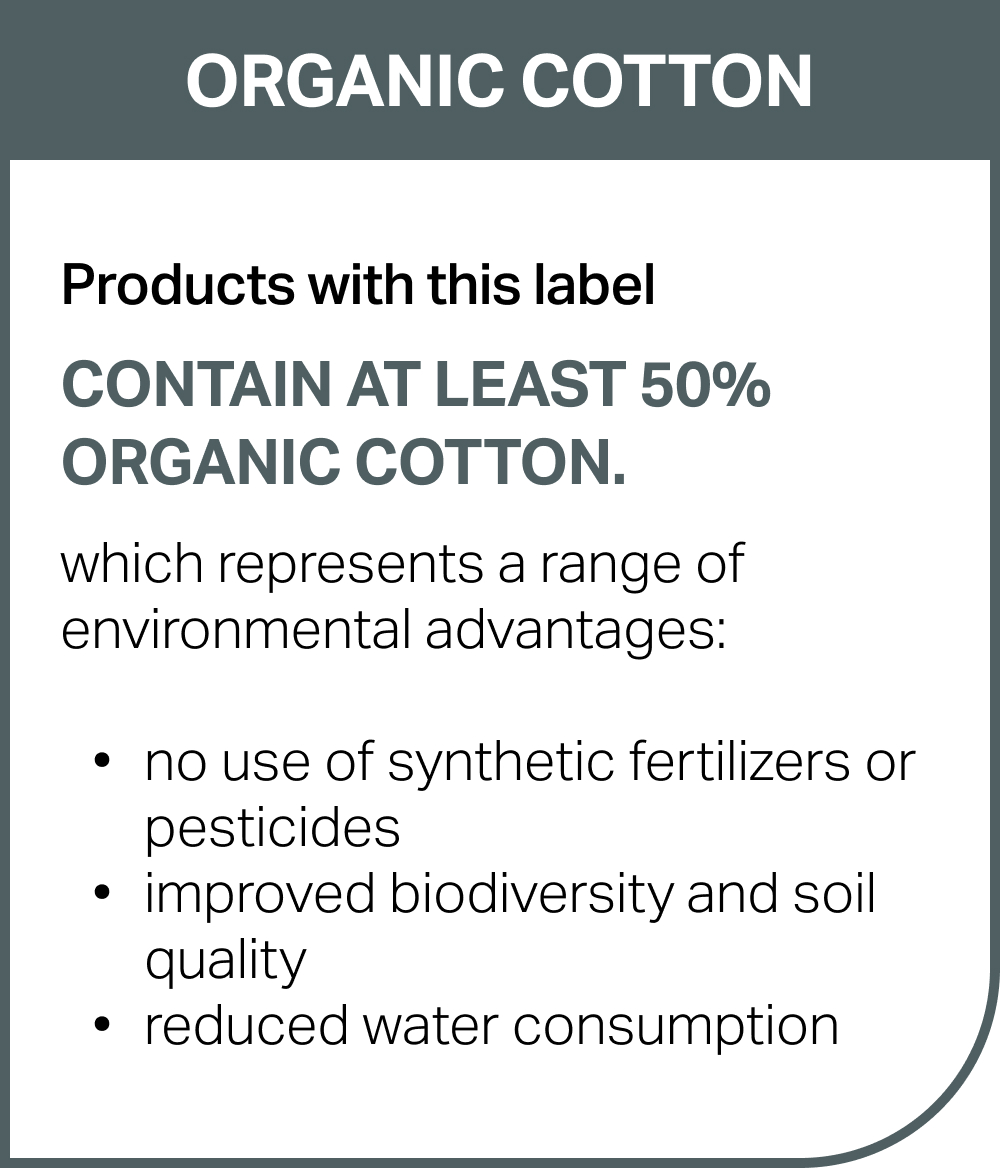

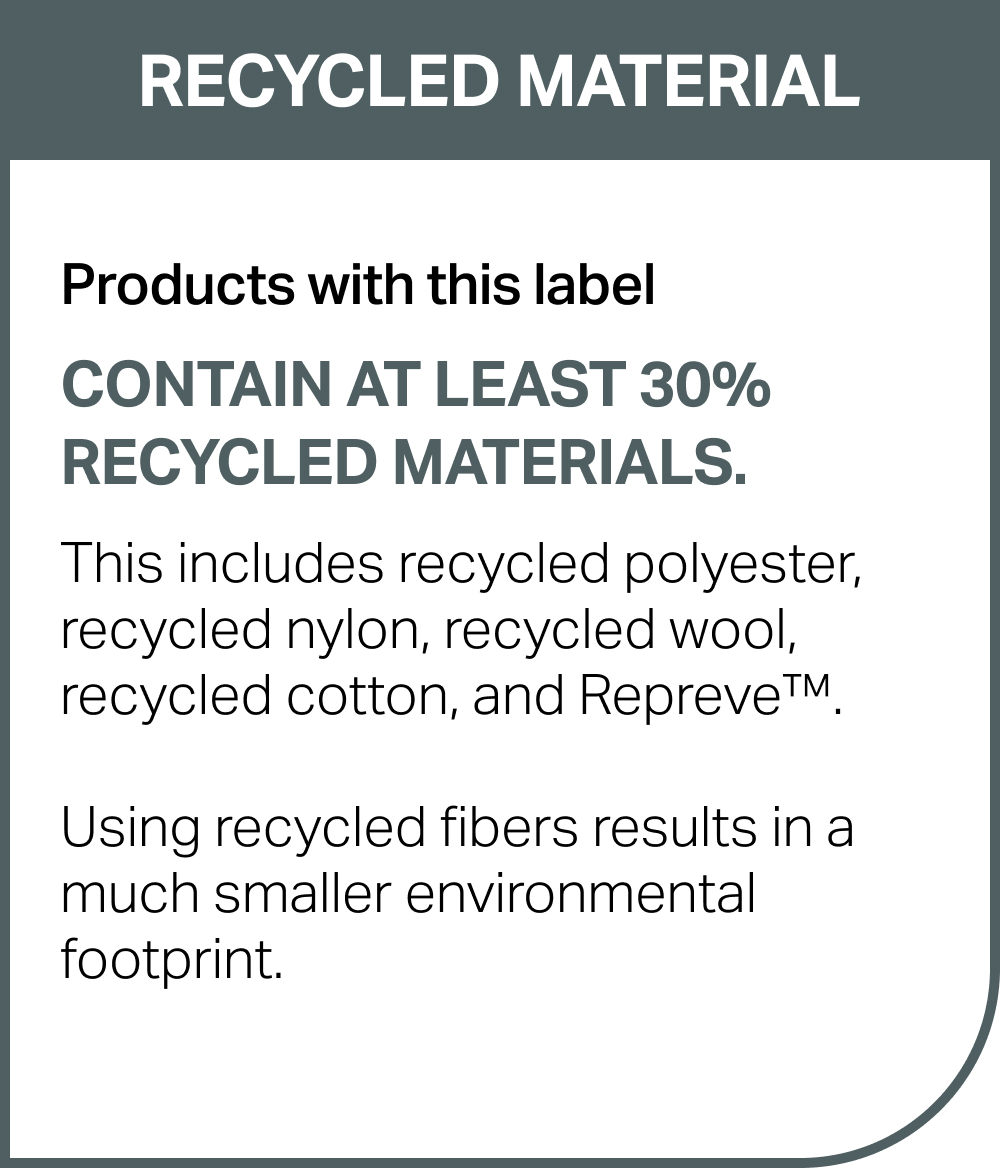

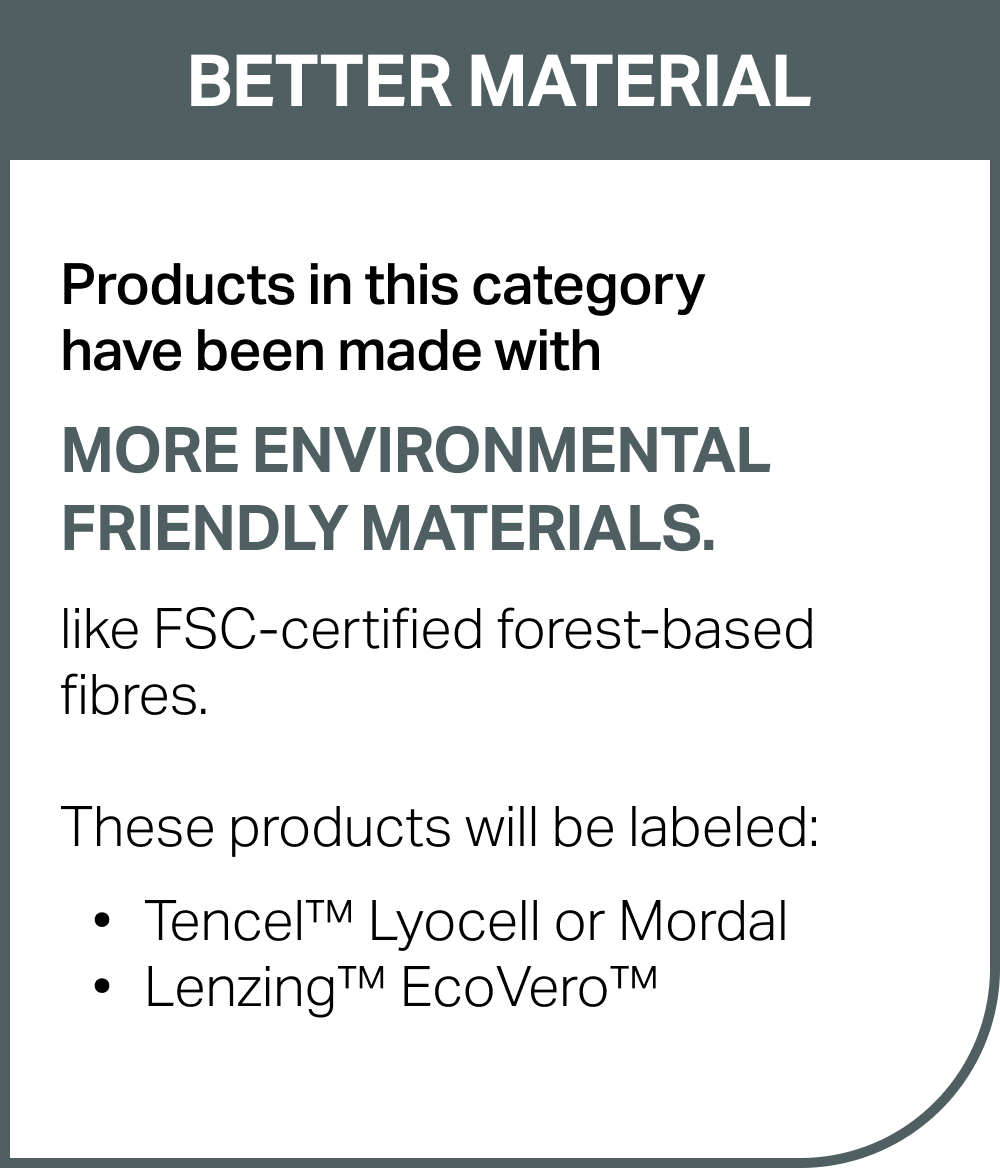

Research shows that the biggest CO2 emissions in the apparel value chain derive from material production. Therefore, to reduce our environmental footprint, it is essential to look at how we can shift from conventional materials and production processes to ones that leave a lower footprint.

For this purpose, designers and purchasers are working with suppliers on finding more sustainable materials and production methods. The approach is to cooperate with suppliers on finding the best solution that makes sense on all parameters. This intensified focus has resulted in several initiatives, such as focus on using organic cotton, recycled materials, and better denim production.

Read about our categories for responsibly made products

Amfori BEPI

It is essential to look at the production methods throughout the supply chain. PWT Group has started engaging strategic suppliers on the amfori BEPI (Business Environmental Performance Initiative) program. Through the BEPI program, suppliers are asked to report on their energy consumption, waste management, chemicals, etc. Based on this, we can assess their priority areas and support them in improving their environmental performance level within these areas.

No harmful chemicals

We are aware of the risk of using harmful chemicals during production, and we are actively working to avoid them, for the sake of both local biodiversity, the environment and the health of the people working in production.

We have set up a Restricted Substance List (RSL) in collaboration with Bureau Veritas. The RSL applies to all garments and accessories manufactured for PWT Group. All suppliers must sign this document before starting production. The RSL is based on the Regulation (EC) No. 1907/2006 of the European Parliament, also known as the REACH regulation, and is updated on a regular basis. For each sales season, styles are picked out for testing at local BV labs, based on a risk assessment.

PWT Group is certified to the OEKO-TEX® Standard 100 and offers a range of certified products. Products certified to the OEKO-TEX® Standard 100 adheres to the strict rules for harmful substances according to the requirements in the standard and covers all components of the product. This helps to ensure product safety for the consumer.

Packaging and Waste Management

A considerable impact, when talking about packaging consumption and waste, is the packaging material used during transportation of our products, such as poly bags, tissue paper, and carbon boxes. We are continuously looking into how to reduce and/or replace existing packaging materials with more sustainable materials. Focus on more recyclable packaging is in line with coming EU legislation within the textile industry.

Waste Management

PWT focuses on handling waste very carefully. The goal is to recycle as much waste as possible.

By implementing targeted waste sorting at PWT Headquarter and warehouse, we will ensure that a large part of the waste is recycled. In 2023 we started collecting data on waste, and we monitor the efforts of sorting in our climate accounting.